Features

Parameters

● Product Features

The machine tool's structure is cast from HT300 material and undergoes a secondary annealing process to completely eliminate casting stress and internal stress caused by rough machining. This ensures structural rigidity and stability, meeting the machine's heavy-duty cutting requirements and ensuring long-term deformation resistance.

The Fanuc system spindle used in this machine tool is fully imported from a professional Taiwanese manufacturer. All key components have undergone reinforcement treatment. The system utilizes world-renowned P4-grade spindle-specific bearings and is lubricated with high-quality grease. After assembly under constant temperature conditions, the entire spindle undergoes computer balancing and run-in testing, ensuring a long service life and high reliability.

The ball screws used in the machine tool's three-axis transmission are all imported. The bearings on both ends of the ball screws utilize imported universal ball screw bearings with a P4-grade contact angle. The ball screws on all three axes are pre-stretched, ensuring strong transmission rigidity and stable, reliable accuracy.

All key components undergo precision scraping (scraping) in accordance with the standards of advanced Taiwanese, Japanese, and German machine tool manufacturers, ensuring that all joints and sliding surfaces achieve precise geometric accuracy, ensuring the expected accuracy and lifespan of the machine.

A comprehensive quality inspection and testing process, utilizing advanced automated optical collimators, laser interferometers, ballbar testers, online dynamic balancers, and other precision testing instruments, as well as a 72-hour run-in test before shipment, ensures that every machine meets its designed performance and expected functionality.

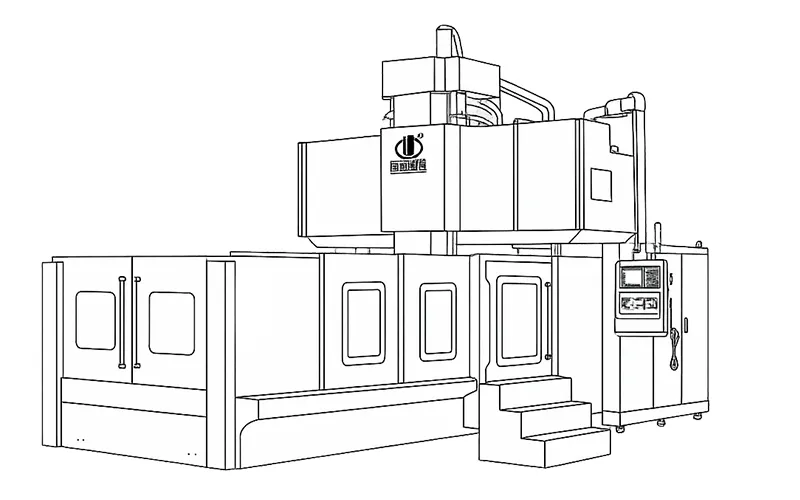

● X-Axis Design Features

The rails utilize renowned imported high-rigidity, high-accuracy Roller-type linear guideways, combining high rigidity for heavy-duty cutting with high-speed, precision performance.

The X-axis utilizes a two- and three-track design with densely packed slides to create a robust structure, maintaining optimal rigidity and flatness, effectively increasing the worktable's load capacity and the dynamic horizontal accuracy of the workpiece.

● Y-Axis Design Features

The machine tool's structure is cast from HT300 material and undergoes a secondary annealing process to completely eliminate casting stress and internal stress caused by rough machining. This ensures structural rigidity and stability, meeting the machine's heavy-duty cutting requirements and ensuring long-term deformation resistance.

The Fanuc system spindles used in the machine tool are fully imported from a professional Taiwanese manufacturer. All key components have undergone reinforcement treatment. They utilize world-renowned P4-grade spindle-specific bearings and are lubricated with high-quality grease. After assembly under constant temperature conditions, the entire spindle assembly undergoes computer balancing and run-in testing, ensuring a long service life and high reliability.

The ball screws driving the machine's three axes are all imported. The bearings on both ends of the ball screws utilize imported universal ball screw bearings with a P4-grade contact angle. The ball screws on all three axes are pre-stretched, ensuring strong transmission rigidity and stable, reliable accuracy.

All key components undergo precision scraping (scraping) in accordance with the standards of advanced Taiwanese, Japanese, and German machine tool manufacturers, ensuring that all joints and sliding surfaces achieve precise geometric accuracy, ensuring the expected accuracy and lifespan of the machine.

A comprehensive quality inspection and testing process, utilizing advanced automated optical collimators, laser interferometers, ballbar testers, online dynamic balancers, and other precision testing instruments, as well as a 72-hour run-in test before shipment, ensures that every machine meets its designed performance and expected functionality.

● Z-Axis Design Features

The Z-axis utilizes a high-rigidity guideway and base support, combined with a gantry frame design, ensuring exceptional stability even during high-load machining, reducing vibration and deformation, and improving machining accuracy.

The high-accuracy linear guideway and preload design ensure smooth and precise Z-axis motion, meeting micron-level machining requirements and delivering exceptional surface quality.

Dynamic balancing and vibration damping effectively reduce vibration during high-speed motion, ensuring stable machining and improving surface quality.

| Workench | Workbench size | 2500x1600mm |

| T-slot (size x quantity x spacing) | 7x22x120mm | |

| Max load of workbench | 7t | |

| Double column distance (door width) | 1800mm | |

| Travel | X-axis travel | 2700mm |

| Y-axis travel | 2000mm | |

| Z-axis travel | 800/1000(opt) | |

Spindle(Fanuc system) Fanuc belt driven8000 | Spindle motor | 18.5/22kw |

| Spindle type | Belt type6000rpm | |

| Taper hole | BT-50/BBT-50/CAT-50 | |

| Feed | Cutting rate | 10m/min |

| Fast feed rate | X:16 / Y:16 / Z:16 m/min | |

| Recommended X/Y/Z Motor parameters | X:7 / Y:6 / Z:7 kw | |

| Accuracy | Positioning accuracy | ±0.013mm/Full stroke |

| Repeated positioning accuracy | ±0.003mm | |

| Automatic tool change | Tool magazine capacity + vertical disc tool magazine | 30pcs |

| Tool change time | 2.91 sec | |

| Max tool weight | 18kg | |

| Max tool length | 400mm | |

| Max tool diameter (full knife/empty knife) | φ112/φ200mm | |

| Tool shank type | BT-50/BBT-50/CAT-50 | |

| Broach bolts | P50T-1/CAT50 | |

| Other | Power | 60kva |

| Air pressure | 8kg/cm² | |

| Net weight | 16.5t | |

| Mechanical weight | 21.45t | |

| Flootprint (L x W x H) | 7900x4800x4500mm |

浙公网安备33071802889448号

浙公网安备33071802889448号