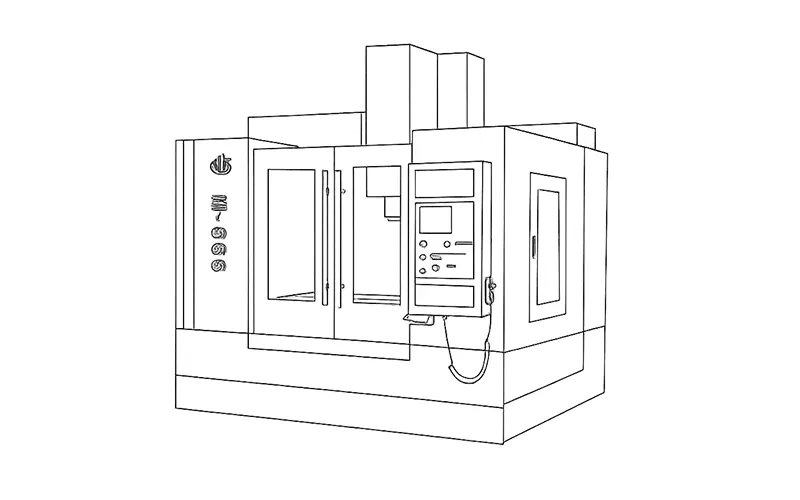

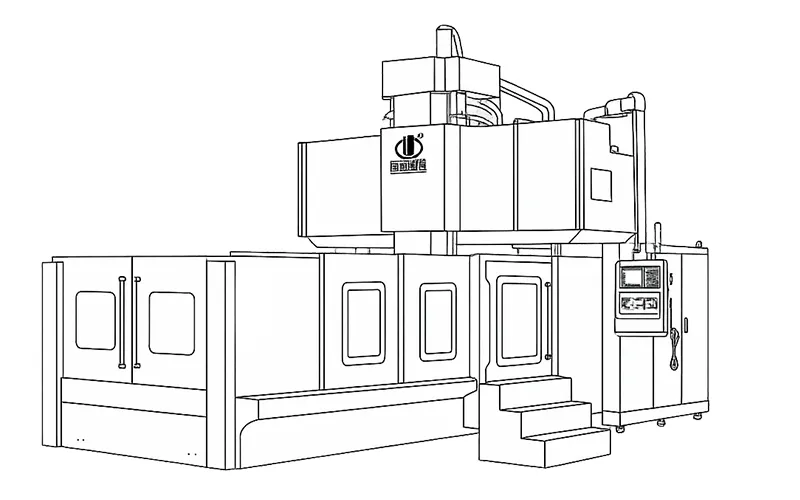

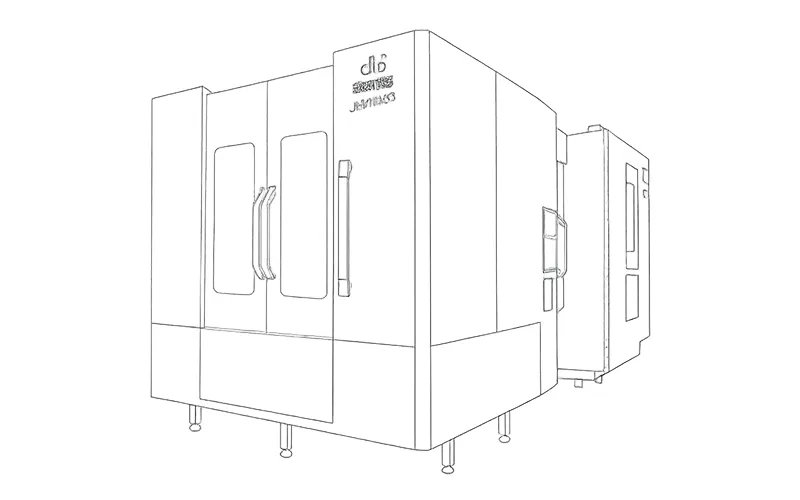

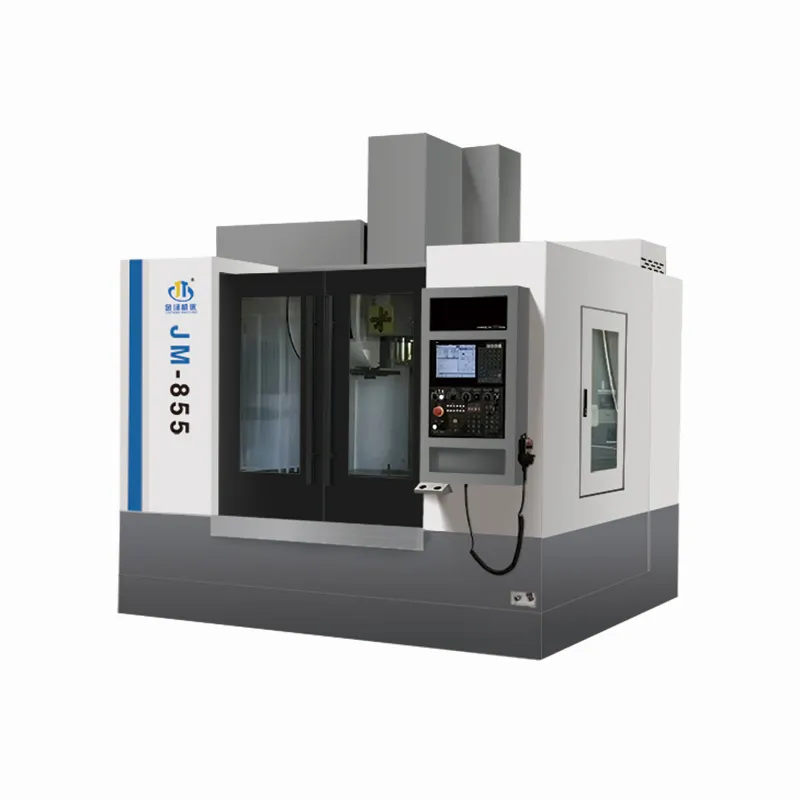

Features

Parameters

● Optimal rigid structure

The castings are made of high-quality Meehanite cast iron and heat-treated to eliminate internal stresses, ensuring long-term deformation resistance.

The machine tool is designed using computer finite element analysis technology. The optimal structural strength and rib combination ensure optimal rigidity and stability.

Compared with the separate base, the one-piece cast base has higher rigidity and better shock suppression effect. The wide base design provides high rigidity required for high-speed machining and heavy load bearing.

The basis surface, sliding surface, and even fixed surface of each machine are hand-scraped to ensure better surface flatness and reliability over a long period of time.

● High Precision and Efficiency

The X and Y axes use imported linear roller slide rails, with high rigidity,low noise and low friction coefficient, and it is suitable for heavy-duty machining. The hardness of the Z-axis rail reaches HS67-75. The precision-ground square rails and the contact surface with TURCITE are precisely scraped. The central lubrication system is also provided to work together to ensure high precision and high stability.

The three axes are directly connected to improve efficiency and ensures stable accuracy.

| Workench | Platform area | 700x1400mm |

| T-slot (size × quantity × spacing) | 5–18x100mm | |

| Max load of bearing capacity | 800kg | |

| Travel | X-axis travel | 1200mm |

| Y-axis travel | 700mm | |

| Z-axis travel | 700mm | |

| Distance from spindle end to worktable | 87–687mm | |

| Distance from spindle center to column | 745mm | |

| Spindle | Spindle power (rated for 30 minutes continuously) | 7.5–11kw |

| Spindle speed (belt-type spindle) | 8000rpm | |

| Taper hole | BT40 | |

| Feed | Cutting rate | 10m/min |

| Fast feed rate(X/Y/Z) | 24/24/24m/min | |

| X/Y/Z feed motor | 3/3/3kw | |

| Accuracy | Positioning accuracy | (±0.005/300,±0.001/Full stroke)mm |

| Repeated positioning accuracy | (±0.005)mm | |

| Automatic tool change | Tool magazine capacity (vertical tool change) | 24pcs |

| Max tool weight | 8kg | |

| Max tool length | 300mm | |

| Automatic tool change tool size (full tool/empty tool) | Φ80/Φ160mm | |

| Tool shank type | BT40 | |

| Other | Power | 30kva |

| Air pressure | 6kg/cm² | |

| Machine tool weight | 8.5T | |

| Footprint (L × W × H) | 3600x2850x2200mm |

浙公网安备33071802889448号

浙公网安备33071802889448号