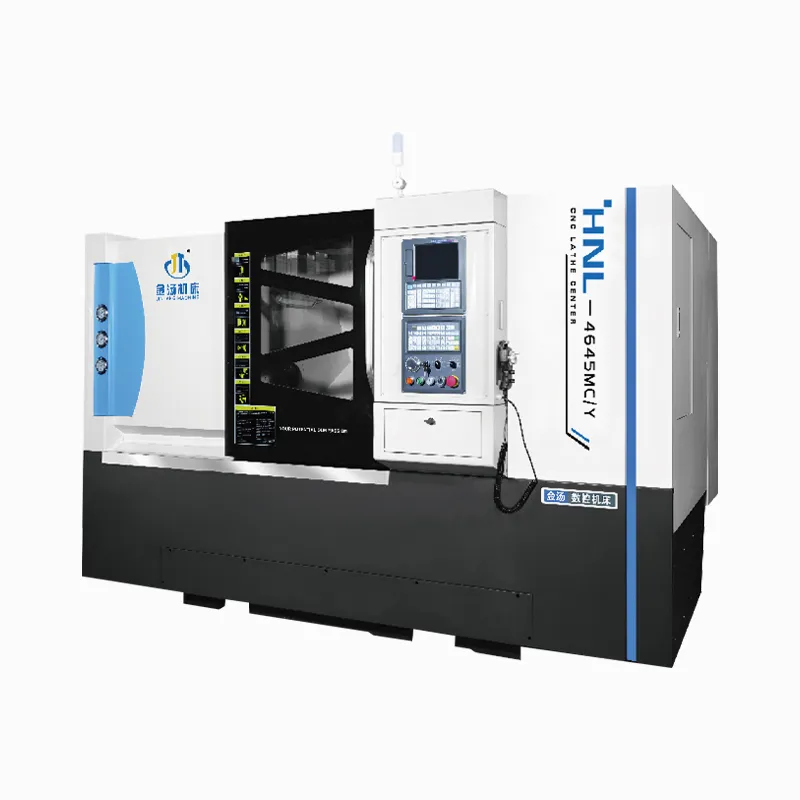

Features

Parameters

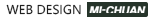

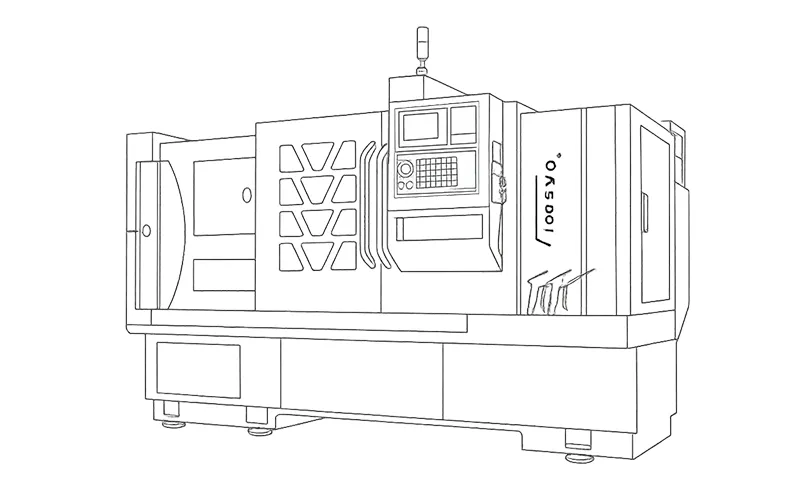

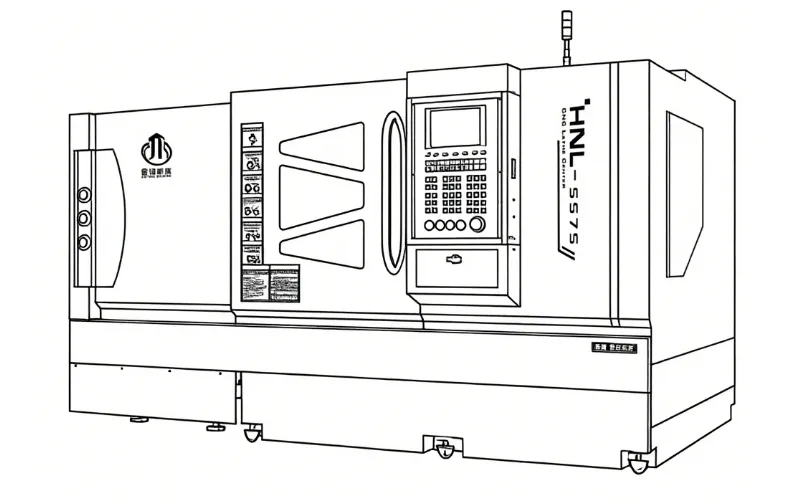

● The overall structure has been optimized for design,featuring a larger working space, less interference and higher cuting speed.

● It uses high-performance cast iron materials, and the main parts have undergone two heat treatments, resulting in good static, dynamic and thermal state stiffness.

● The bed body is arranged in a 30°position, facilitating chip removal and easy integration with an automated production line.

● Numerical Control System: Standard configuration: FANUC 0i TF (3B). Optional configurations: New Generation, Siemens, Huazhong Numerical Control.

| Capacity | Guide ways type | Linear guide rails |

| Bed angle | 30° | |

| Swing over bed | φ600mm | |

| Swing over saddle | φ320mm | |

| SpindleMax turning diameter | φ320mm | |

| Max turning length | 510(480)mm | |

| Spindle | Draw bar hole diameter | φ65mm |

| Bar capacity | φ52mm | |

| Max spindle speed | 4000rpm | |

| Spindle drive motor (continuous/30 minutes) | ||

| Spindle torque | 177N.m | |

| Spindle 2 nose type | A2-6 | |

| Cs-axis C | 0.001 deg | |

| Chuck size | 8 inch | |

| Sub-spindle | Draw bar hole diameter | φ56(φ65)mm |

| Bar capacity | φ42(φ52)mm | |

| Max spindle speed | 5000(4000)rpm | |

| Spindle drive motor (continuous/30 minutes) | Electric spindle7.5/11KW | |

| Spindle torque | 48N.m | |

| Spindle 2 nose type | A2-5(A2-6) | |

| Chuck size | 6(8) inch | |

| Turrte | Turret type | Horizontal powered tool holder BMT45(BMT55) |

| Number of tool station | 15(12) | |

| OD. tool size | 20x20(25x25)mm | |

| Max boring bar size | φ32(φ40)mm | |

| Rotary tool power | 2.7(3.7)KW | |

| Max rotary tool speed | 4000rpm | |

| Rotary tool torque | 12(18)N.m | |

| Travel | X-axis travel | 260mm |

| Z-axis travel | 620mm | |

| Y-axis travel | ±50(±55)mm | |

| W-axis travel | 520mm | |

| Feed rate | X/Y/Z/W-axis rapid feed rate | 24/24/12/12m/min |

| Accuracy | X/Y/Z/W-axis positioning | 0.01/0.01/0.12/0.12mm |

| C/C2-axis positioning | 0.01deg | |

| X/Y/Z/W-axis repeatability | 0.005mm | |

| C/C2-axis repeatability | 0.006deg | |

| Other | Coolant pressure | 10bar |

| Dimensions (L x W x H) | 2850x1750x2040mm(Without chip conveyor) | |

| Net weight | 3800kg | |

| Controller | FANUC Oi TF(3B) |

浙公网安备33071802889448号

浙公网安备33071802889448号