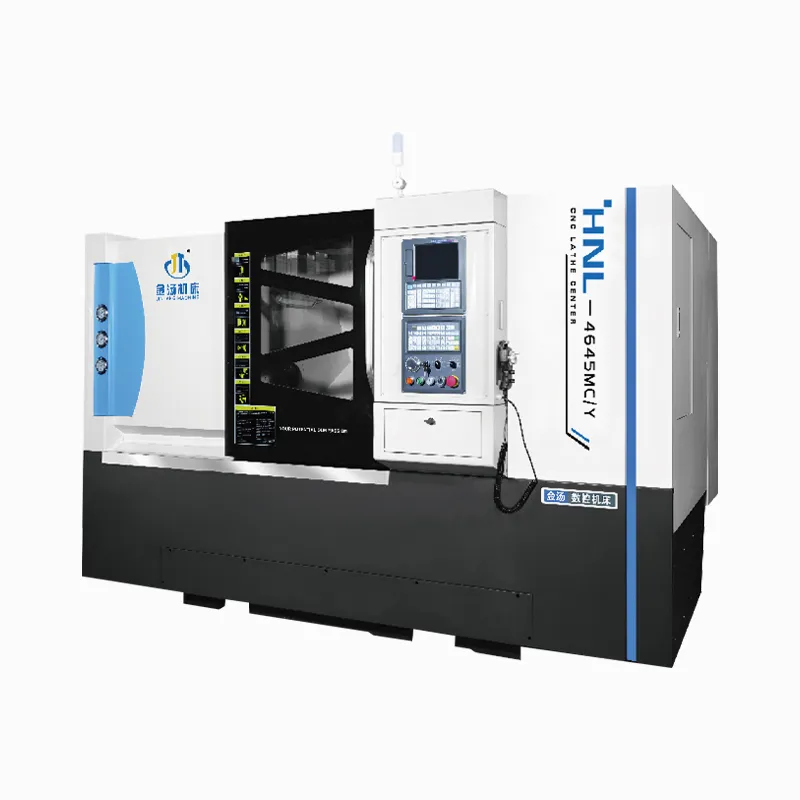

Features

Parameters

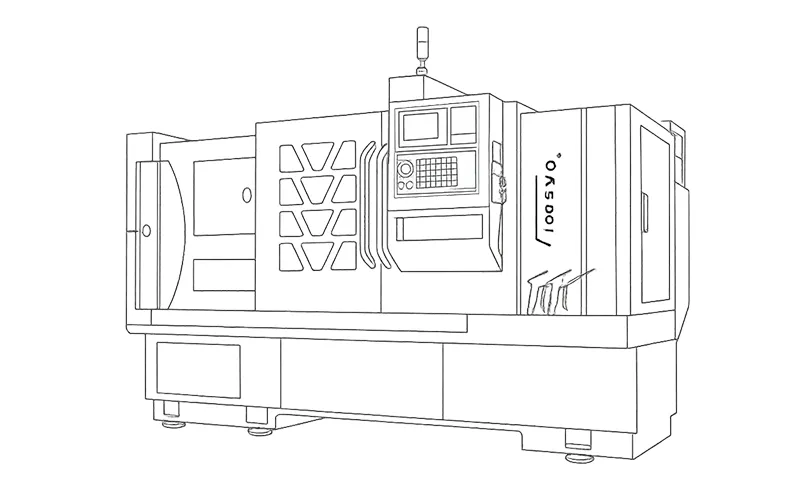

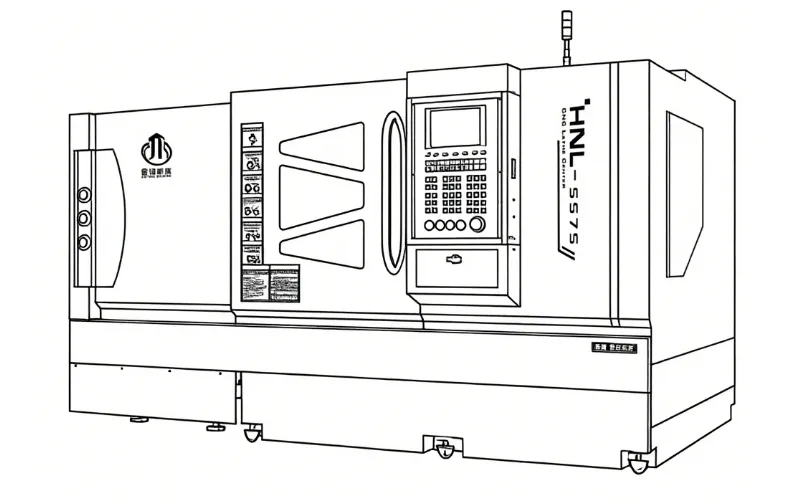

● The overall structure has been optimized to provide a larger working space, smaller interference, higher cutting speed and more compact installation space.

● Made of high-performance cast iron, the main parts have undergone two thermal aging processes, and have excellent static, dynamic and thermal stiffness.

● The guide rails at the front end of the bed are arranged at 30° or 45°, which ensures smooth chip removal and makes it easy to form an automated production line.

● Numerical control system: Standard configuration: FANUC 0i TF (3B); Optional configuration: New Generation, Kainite, Siemens.

| Capacity | Bed angle | 45° |

| Guide ways type | Linear guide rails(Roller) | |

| Max turning diameter of machine tool | φ660mm | |

| Max turning diameter of carriage | φ460mm | |

| Max processing diameter | φ420mm | |

| Max turning length | 760(1000/1500/2000)mm | |

| Spindle | Main shaft structure | Sleeve spindle outer diameter240(280) |

| Main shaft nose type | A2-8(A2-11) | |

| Main shaft through hole diameter | φ87(φ105)mm | |

| Bar capacity | φ72(φ92)mm | |

| Max spindle speed | 3000(2500)r/min | |

| Max spindle torque | 220(300)N.m | |

| Main motor power | 15/18.5KW | |

| C-axis indexing | 0.001 deg | |

| Chuck size | 10(12) inch | |

| Turrte | Turret type | BMT65 |

| Number of tool station | 12 | |

| OD. tool size | 25x25mm | |

| Max boring bar size | φ50mm | |

| Power tool power | 5.6-7.5KW | |

| Max speed of power tool | 4000rpm | |

| Max torque of driven tool holder | 47N.m | |

| Feed parameters | Modei of X-axis guide rail | 45Roller |

| Modei of Z-axis guide rail | 45Roller(55Roller) | |

| Model of X-axis lead screw | 4010-C | |

| Model of Z-axis lead screw | 5012-C33 | |

| Lead screw bearings | 3062-P4/4090-P4 | |

| Travel | X-axis max travel | 270mm |

| Z-axis max travel | 820mm | |

| Fast movement speed | X-axis rapid traverse speed | 24m/min |

| Z-axis rapid traverse speed | 24m/min | |

| Feed Motor | X-axis feed motor | 3.0KW |

| Z-axis feed motor | 3.0KW | |

| Tailstock | Tailstock structure | Sliding hard rail |

| Turning center type | Rotating top Mohs 5 | |

| Tailstock travel | 680mm | |

| Tailstock movement | Tractor driven | |

| Tailstock quill diameter | φ120mm | |

| Centering travel | 150mm | |

| Accuracy | X-axis repeatability | 0.006mm |

| Z-axis repeatability | 0.007mm | |

| C-axis repeatability | 0.006deg | |

| X-axis positioning | 0.01mm | |

| Z-axis positioning | 0.014mm | |

| C-axis positioning | 0.01deg | |

| Other | Coolant pressure | 10bar |

| Protection type | Fully enclosed | |

| Independent chip conveyor | Side row | |

| Water tank (capacity) | 150L | |

| Dimensions (L x W x H) | 3800x2290x2320mm | |

| Machine tool weight | 7500kg | |

| Numerical control system | FANUC Oi TF(3B) |

浙公网安备33071802889448号

浙公网安备33071802889448号