Features

Parameters

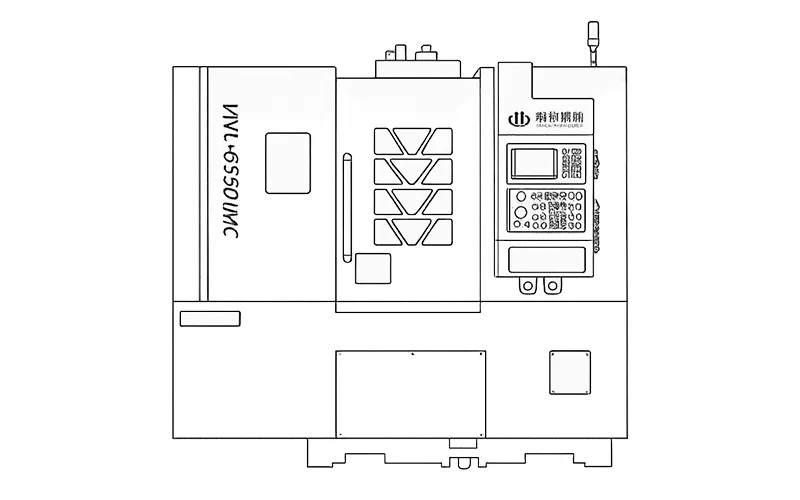

● The castings are cast using resin sand technology, with beautiful appearance and small deformation.

● Integral bed base: The bed base adopts a thermally symmetrical box-stiffened cast iron structure to minimize thermal deformation and provide strong support during heavy cutting. The chip discharge surface inside the bed base adopts a large inclination angle to prevent the accumulation of iron chips.

● Sleeve-type spindle: The spindle unit adopts a sleeve-type structure to facilitate assembly and maintenance. The spindle unit is a high-rigidity bearing support structure. The spindle has good rigidity, high rotation accuracy, long life, low temperature rise, and good accuracy retention.

● Spindle drive: Using high-power spindle motor, the spindle has C-axis indexing function. With spindle indexing encoder and hydraulic brake

● It adopts an integrated design of electromechanics, hydraulics and gas, equipped with a 12-station turret, BT40 drilling and milling spindle, and a disc tool magazine, so that it can complete multi-process processing in one clamping.

● Z-axis balance design: Equipped with nitrogen balance system to reduce screw load and extend screw service life.

Optional configuration

● Guangzhou CNC, Kaindi, FANUC

● Zhongshi hydraulic chuck, indexing chuck

● Automatic chip conveyor

| Maximum turning diameter on the bed | φ650mm | |

| Maximum machining diameter | φ500mm | |

| Maximum processing length | 500mm | |

| Indexing chuck | φ500mm | |

| Spindle nose | A2-8 | |

| Spindle hole diameter | φ65mm | |

| Spindle maximum speed | 2000rpm | |

| Main motor power | 15/18.5kw | |

| Turret type | 125-480-12 | |

| Knives | φ32/φ50mm | |

| Motor Power | 7.5/11kw | |

| Specification | BT40pulley type | |

| Maximum speed | 4000rpm | |

| Tool magazine | 16 knife disc type | |

| Iiquid nitrogen balance | Nitrogen bottle + balancing cylinder | |

| X/Z axis maximum travel | 430/550mm | |

| X/Z axis rapid traverse speed | 24/24m/min | |

| X/Z axis rail specifications | 45/45 roller | |

| X/Z axis screw specifications | φ32x08/φ40x10 | |

| X/Z axis motor torque | 15/22N.m | |

| Hydraulic pump motor | 2.2kw | |

| Type | Volumetric quantitative lubrication | |

| Cooling pump power | 0.37kw | |

| High pressure pumps | 3.0MPa | |

| Chain plate rear row | Optional side rows | |

| Machine weight | 7000g | |

| Machine tool dimensions (length × width × height) | 2400x2400x2800mm | |

浙公网安备33071802889448号

浙公网安备33071802889448号