Features

Parameters

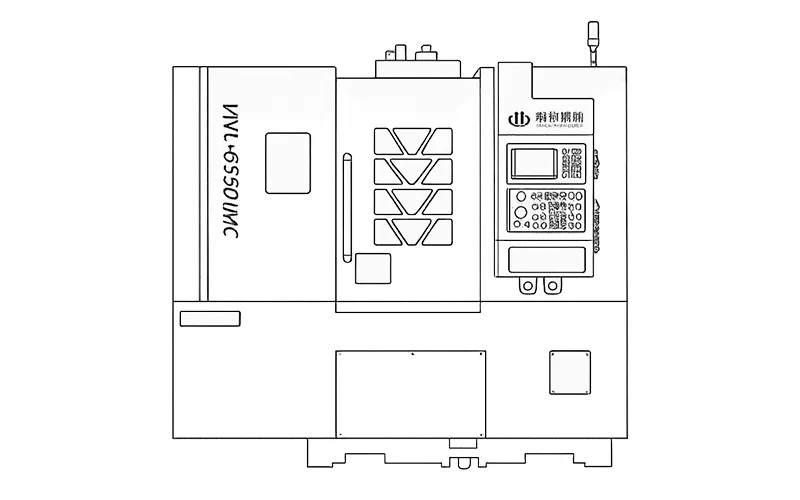

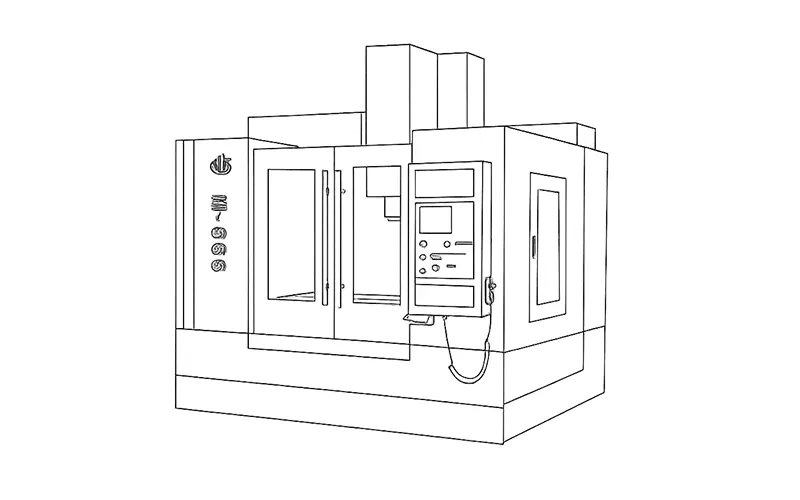

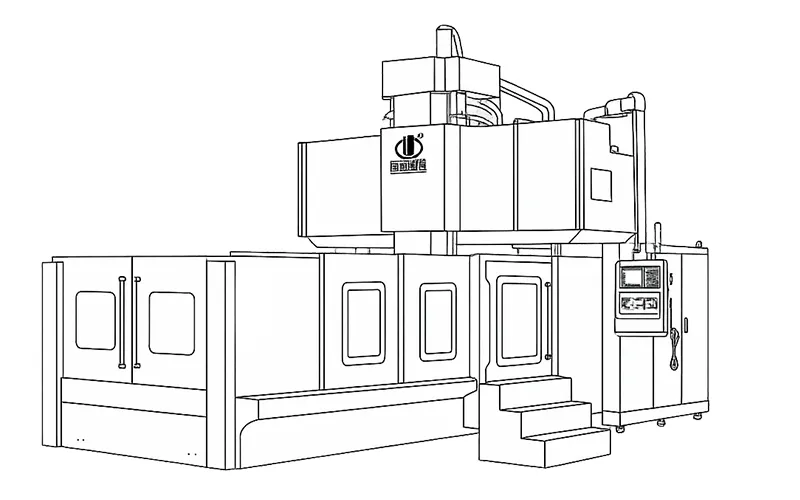

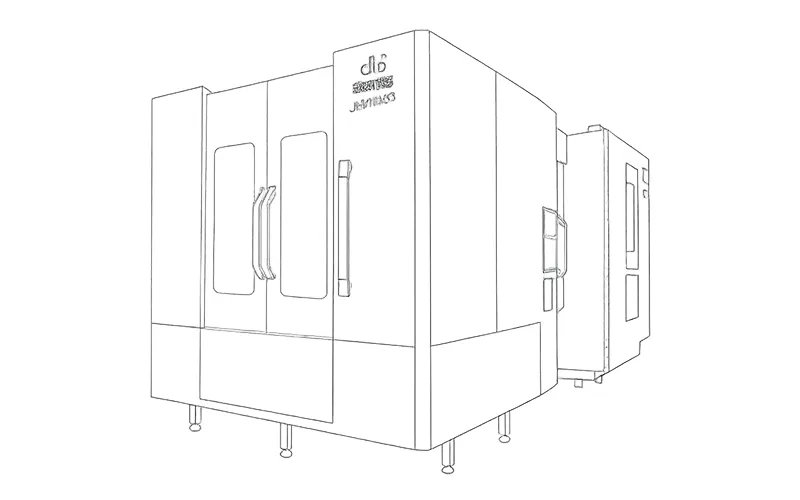

● The column adopts a hollow double-layer box structure with left-right symmetrical design and high-strength cross-rib arrangement, enabling the column to withstand the heavy cutting torque during high-speed operation.

● The base adopts a T-shaped integrated box structure design,combined with reinforced internal ribs and ultra-wide linear guide rail span,ensuring the stability and machining accuracy of the machine tool during the cutting process.

● X, Y, and Z axes are equipped with imported heavy-load ball roller linear guides to enhance the stability of the three-axis movement.

● Special imported ball screw bearings are used, with pre-tensioning treatment to prevent thermal displacement. Imported couplings ensure the rigidity and stability of the transmission.

● The ballscrew undergoes pre-tensioning treatment, minimizing the thermal deformation of the screw.

● The minimum division of the worktable is 1°(0.001° is selected),and both single and double worktables have high rotational accuracy and excellent dynamic performance.

| Workench | Rotation worktable size | 800x800mm |

| Worktable indexing | 1°/0.001°drg | |

| Workbench T-slot (number of slots - size x spacing) | 7-18x100mm | |

| Number of worktables | 1/2pcs | |

| Max load of workbench | 2000kg | |

| Positioning accuracy | 6″/10″sec | |

| Repeated positioning accuracy | ±2″/+4″sec | |

| Travel | X-axis travel | 1100mm |

| Y-axis travel | 900mm | |

| Z-axis travel | 1040mm | |

| Distance from spindle center to work table | 150-1050mm | |

| Distance from spindle nose to worktable center | 160-1200mm | |

| Spindle | Spindle type | Belt type/Gear type |

| Spindle motor | 22/26kw | |

| Taper hole | BT-50/BBT-50 | |

| Feed | Cutting rate | 10m/min |

| Fast feed rate | X: 24、Y: 24、Z: 24 m/min | |

| XYZRecommended torque for XYZ-axis servo motors | X/30、Y/30(brake)、Z/30 N.m | |

| Accuracy | Positioning accuracy | 0.01mm |

| Repeated positioning accuracy | 0.005mm | |

| Automatic tool change | Tool magazine capacity | 40/60pcs |

| Max tool weight | 25kg | |

| omatic tool chanTool length for automatic tool change | 500mm | |

| Max tool size for automatic tool change (full tool /out-of-the chuck tool) | φ125/φ225mm | |

| Tool shank type | BT-50/BBT-50 | |

| Other | Power | 35kva |

| Air pressure | 6-8kg/cm² | |

| Mechanical weight | 18.5T | |

| Flootprint (L x W x H) | 5839x4636x3090mm |

浙公网安备33071802889448号

浙公网安备33071802889448号