Features

Parameters

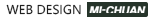

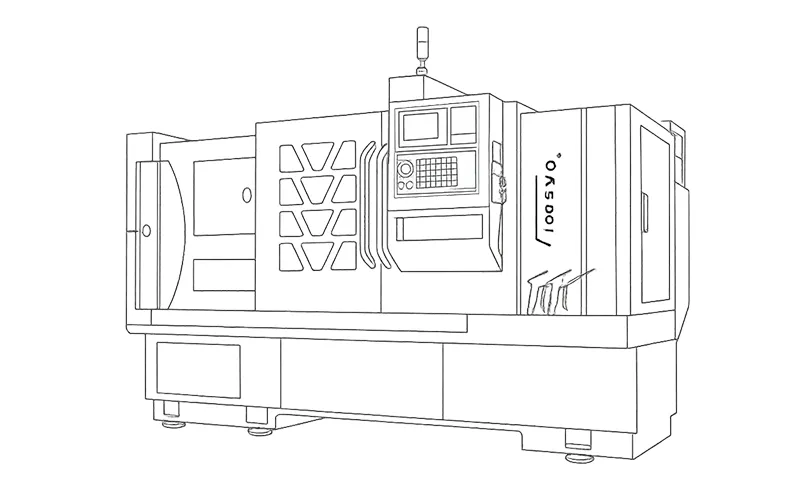

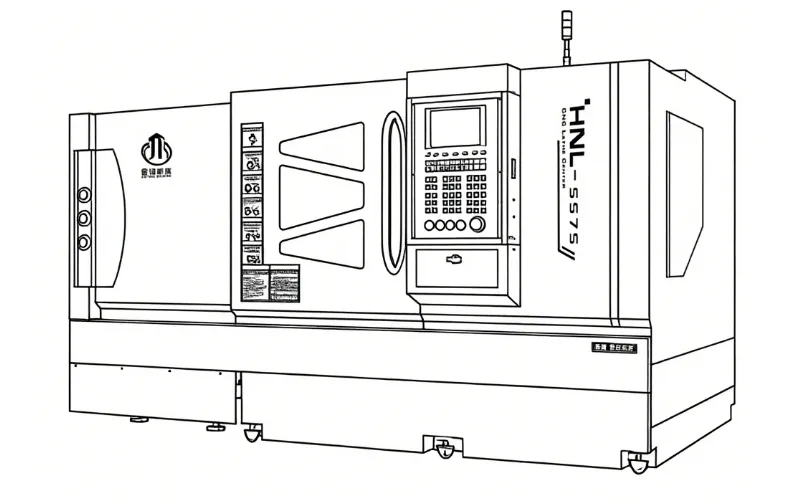

● Castings are cast by resin sand process, with beautiful appearance and small deformation of castings. All castings are treated with secondary aging, and the thermal deformation is small.

● The whole bed foot, casting an integrated water tank, the waterproof performance is much better than similar products, the width of the guide rail is 420mm, which is better than similar products.

● The bed guide rail is quenched by super audio frequency, the hardness is HRC55, the thickness is more than 3mm, and it has extremely high precision retention.

● The high-rigidity spindle system with three-point support and four-way bearing is adopted, and the absolute temperature rise is less than 25℃. It is especially suitable for the processing of parts that require high dimensional accuracy and surface finish and require heavy cutting.

● The machine tool adopts three-speed frequency conversion, the main motor adopts frequency conversion spindle motor, and the standard configuration high-quality frequency converter has large output torque at low speed.

● The tailstock has a double locking mechanism, and the bottom is equipped with an unloading device to move the Tailstock lightly and effortlessly.

● The use of enlarged and thickened large carriages and middle carriages makes the machine tool more rigid, and the cutting is more stable and powerful.

● The appearance protection of the 1500/2000 model from the top is a double-door semi-closed type.

| Model | CK630(CK530heighten) | CK530 | ||

| Processing range | Maximum turning diameter of bed(mm) | 640 | 540 | |

| Skateboard swing diameter(mm) | 390 | 290 | ||

| Maximum cutting length (mm) (two centers) | 750/1000/1500/2000 | 750/1000/1500/2000 | ||

| Spindle | Spindle end form and code | C-8 | C-8 | |

| Spindle center height | 315 | 265 | ||

| Spindle speed range(r/min) | 25~340/60~780/120~1600 | 25~340/60~780/120~1600 | ||

| Spindle speed series | third gear | third gear | ||

| Spindle diameter(mm) | Φ82 | Φ82 | ||

| Spindle taper hole | Metric 90 | Metric 90 | ||

| Main motor power(Kw) | 7.5KW(132M) | 7.5KW(132M) | ||

| Rail span | 420 | 420 | ||

| Chuck | Manual | Φ250 | Φ250 | |

| Pneumatic | Special match | Special match | ||

| Hydraulic | Special match | Special match | ||

| Spring collet | Special match | Special match | ||

| Feed | Feed motor torque(x/z) | 7.7/10 | 7.7/10 | |

| Z-axis travel(mm) | 750/1000/1500/2000 | 750/1000/1500/2000 | ||

| X-axis travel(mm) | 380 | 380 | ||

| Fast movement speed(X/Z)(m/min) | 6/8 | 6/8 | ||

| Minimum input unit(mm) | 0.001 | 0.001 | ||

| Tool holder | Four-station tool post | Standard configuration | Standard configuration | |

| Six-station tool holder | Special match | Special match | ||

| Tool holder | Special match | Special match | ||

| Tailstock | Sleeve diameter(mm) | Φ75/85 | Φ75/85 | |

| Sleeve stroke(mm) | 150 | 150 | ||

| Cone taper | Morse 5 | Morse 5 | ||

| Control System | KND1000T | Standard configuration | Standard configuration | |

| Guangshu 980TD | Special match | Special match | ||

| Fanuc, Siemens, Mitsubishi | Special match | Special match | ||

| Machine size (length * width * height) (mm) | 750mm:2550*1360*1650 | 750mm:2550*1360*1650 | ||

| 1000mm:2800*1360*1650 | 1000mm:2800*1360*1650 | |||

| 1500mm:3300*1360*1650 | 1500mm:3300*1360*1650 | |||

| 2000mm:3800*1360*1650 | 2000mm:3800*1360*1650 | |||

| Machine weight(kg) | 2700~3500 | 2700~3500 | ||

浙公网安备33071802889448号

浙公网安备33071802889448号