Features

Parameters

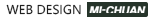

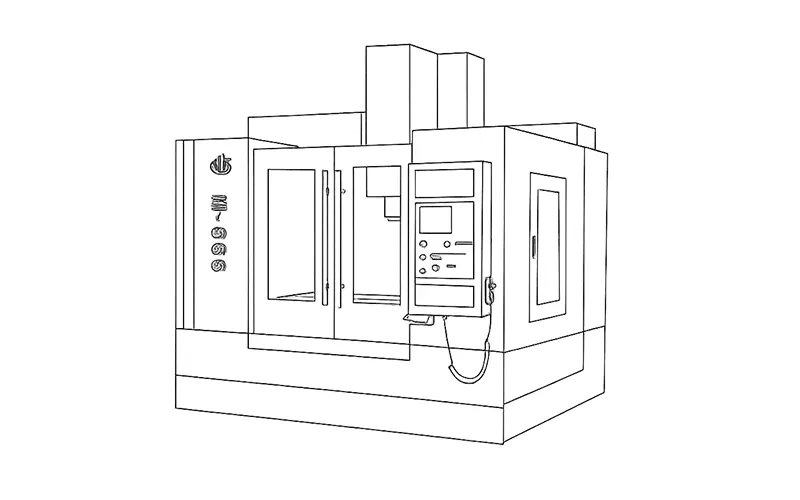

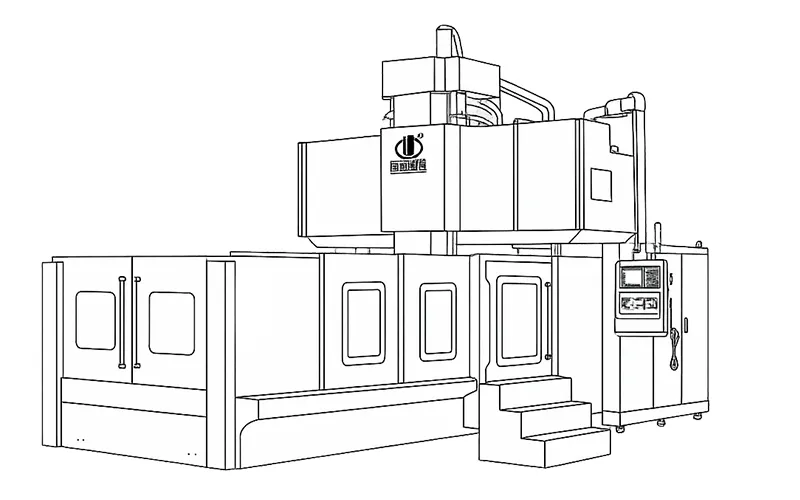

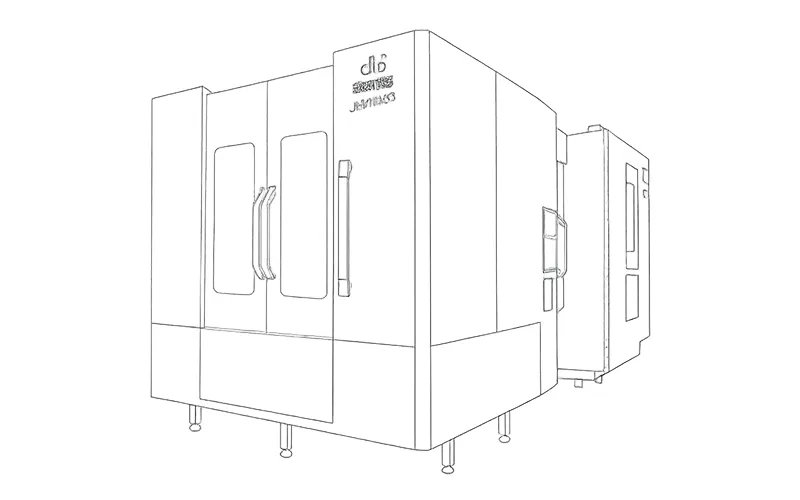

● The castings are cast using resin sand technology, with beautiful appearance and small deformation.

● This machine tool is a two-coordinate horizontal CNC lathe. It is mainly responsible for various turning processes. Through the control of a microcomputer program, it can turn complex surfaces such as inner and outer cylindrical surfaces, circular surfaces, grooving, arcs and spherical surfaces of various parts. It can also perform drilling, reaming, drilling, drilling, tapping and other processing.

● Mature and reliable high-rigidity spindle pump, medium 86 spindle aperture, 520mm double triangular guide rail, central screw, good guidance, stability and versatility. The bed guide rail adopts super audio frequency fire reduction, good wear resistance, guaranteed Precision lasts. There is a wide chip removal hole under the chuck, and the ball screw is effectively protected.

● The X and Z sliding saddles are both wide and thick, with large contact surface and large stroke. Their rigidity, stability, durability, versatility and scalability are extremely rare among machine tools of the same level. It can be equipped with various specifications of tool holders, turrets, rows of tools, and power heads, or they can be mixed.

● The main pumping speed can reach 2000rpm. The through hole is 86, the rotation diameter on the bed is 740mm, the processing straightness on the slide plate is 327mm, the X-direction stroke is up to 520mm, and the X-direction stroke is up to 690mm. The knife installation type is flexible, the power head can be installed, and the tail can be optional seat, its processing capabilities and range are particularly outstanding.

● The bed and foot are integrally cast, with a reasonable and beautiful layout. Installation, handling, cooling, protection, pipeline layout, etc. are all carefully considered, which not only highlights the accuracy and rigidity of the machine tool, but also takes into account practicality and pleasantness. The structure is reasonable and the protection is beautiful.

| Model | CK680 | ||

| Processing range | Maximum rotation diameter of bed(mm) | Φ740 | |

| Maximum rotation diameter on large carriage(mm) | Φ700 | ||

| Maximum rotation diameter of the middle pallet(mm) | Φ327 | ||

| Maximum processing length(mm) | 550/750/1000 | ||

| Spindle | Spindle end and type code | A2-8 | |

| Spindle center height | 340mm | ||

| Spindle speed range | 200~2000r/min | ||

| Spindle speed series | Stepless | ||

| Spindle bore diameter(mm) | Φ86 | ||

| Spindle taper hole | Metric 93 | ||

| Main motor power | 15kw(Servo) | ||

| Rail span | 520/Double triangular guide rail/screw center | ||

| Chuck | Manual | Φ250/three claws | |

| Pneumatic | Special allocation (by user) | ||

| Hydraulic | Special allocation (by user) | ||

| Spring collet | Special allocation (by user) | ||

| Feed | Feed motor torque(x/z) | 7.5/10 | |

| Z-axis travel(mm) | 630/830/1080 | ||

| X-axis travel (mm) | 520 | ||

| Fast movement speed(X/Z)(m/min) | 6/8 | ||

| Minimum input unit(mm) | 0.001 | ||

| Knife holder | Four-station tool holder | Standard configuration | |

| Six-station tool holder | Special configuration | ||

| Tool holder | Special configuration | ||

| Tailstock | None (optional) | ||

| Control System | Guangshu 980 | Special configuration | |

| Kanedi KND1000T | Standard configuration | ||

| Fanuc, Siemens, Mitsubishi、FAUNC、SIEMENS、MITSUBISHI | Special configuration | ||

| Machine size (length × width × height) | 550mm: 2540x1920x1780mm | ||

| 750mm: 2740x1920x1780mm | |||

| 1000mm: 2990x1920x1780mm | |||

| Machine weight(kg) | 2600~3000 | ||

浙公网安备33071802889448号

浙公网安备33071802889448号