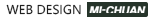

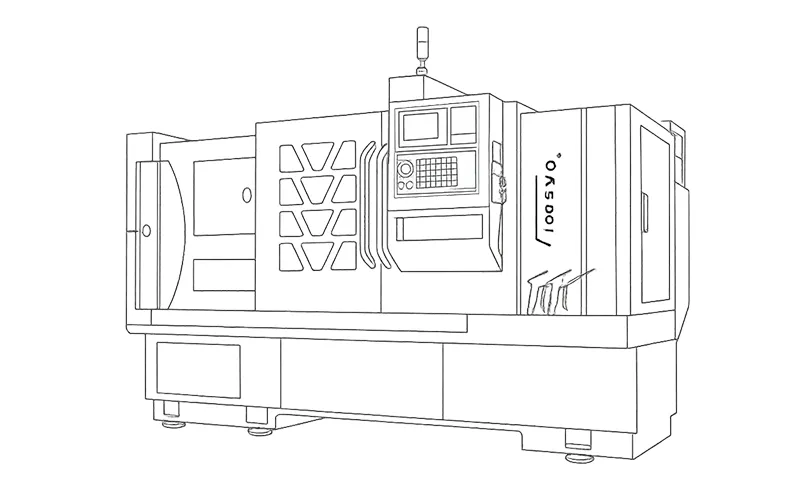

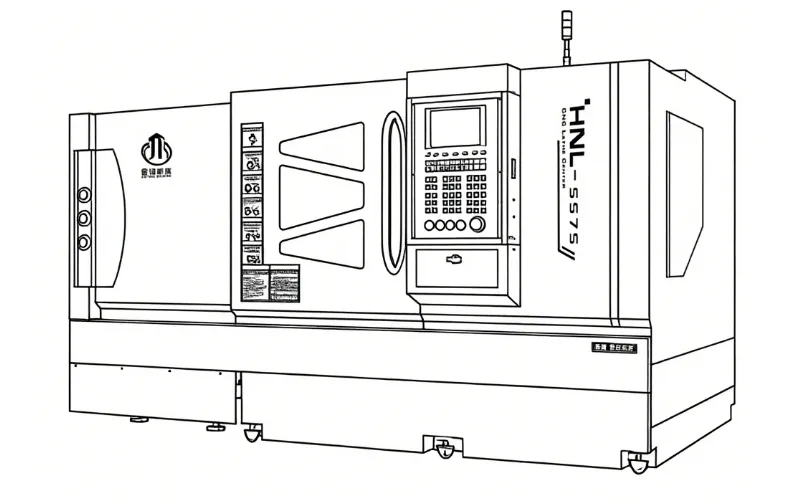

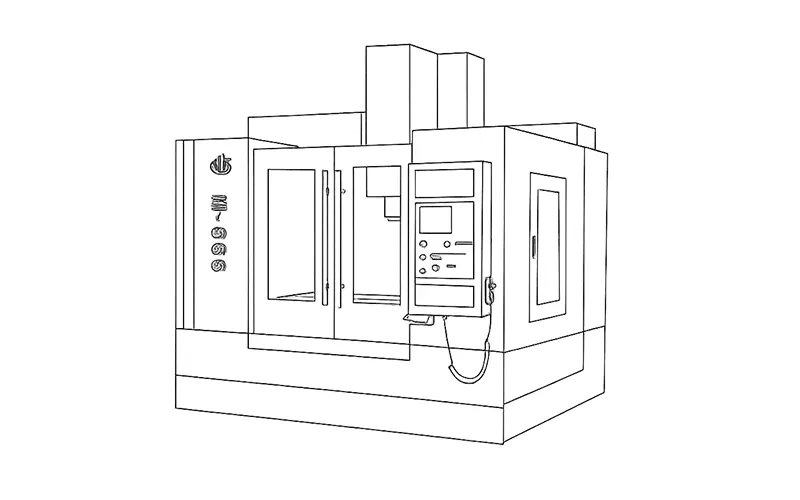

Features

Parameters

● Castings are cast by resin sand process, with beautiful appearance and small deformation of castings. All castings are treated with secondary aging, and the thermal deformation is small.

● Integral bed foot, cast integrated water tank, with a clearing tank, the water pipe is not easy to be blocked, and the performance is better than similar products.

● The width of the bed guide is 350mm, and the stability and rigidity of the machine tool are high.

● The bed guide rail is quenched by super audio frequency, the hardness is HRC55, the thickness is more than 3mm, and it has extremely high precision retention.

● Headstock with heat sink structure, low temperature rise.

● The diameter of the main shaft is Φ58, and the range of use is large.

● Adopting independent spindle structure, it is especially suitable for the processing of small and medium-sized parts with high dimensional accuracy and surface roughness requirements. (CK6136HS/CK6140HS is a servo spindle structure)

● The work light uses the most energy-efficient LED tubes.

● Fully sealed protection design, exquisite and generous structure.

| Model | CK6140H | ||

| Processing range | Maximum turning diameter of bed(mm) | Φ420 | |

| Skateboard swing diameter(mm) | Φ226 | ||

| Maximum cutting length (mm) (two centers) | 750 | ||

| Spindle | Spindle speed range | 200~2500 | |

| Spindle speed series | CVT | ||

| Spindle diameter(mm) | Φ58 | ||

| Spindle taper hole | Morse 6 | ||

| Chuck | Manual | Φ250 | |

| Pneumatic | |||

| Hydraulic | |||

| Spring collet | |||

| Specification | |||

| Feed | Main motor power(kw) | 5.5kw | |

| Z-axis travel(mm) | 650 | ||

| X-axis travel(mm) | 250 | ||

| Fast movement speed(X/Z)(m/min) | 6/8 | ||

| Minimum input unit(mm) | 0.001 | ||

| Feed motor torque(x/z) | 4/6 | ||

| Tool holder | Four-station tool post | Standard configuration | |

| Six-station tool holder | |||

| Arrange the knife holder | |||

| Control System | Guangshu 980 | Special match | |

| KND1000T KND1000T | Standard configuration | ||

| Fanuc, Siemens, Mitsubishi | Special match | ||

| Machine size (L × W × H) | 2165x1390x1565mm | ||

| Machine weight(kg) | about 2200 | ||

浙公网安备33071802889448号

浙公网安备33071802889448号