Features

Parameters

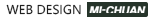

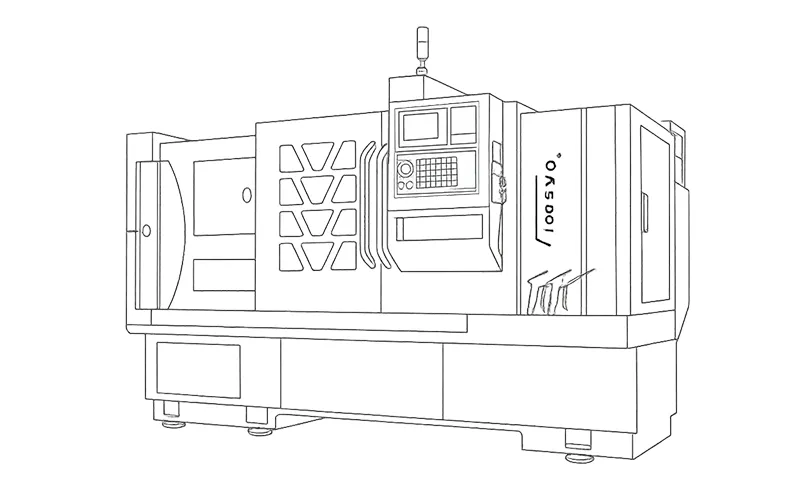

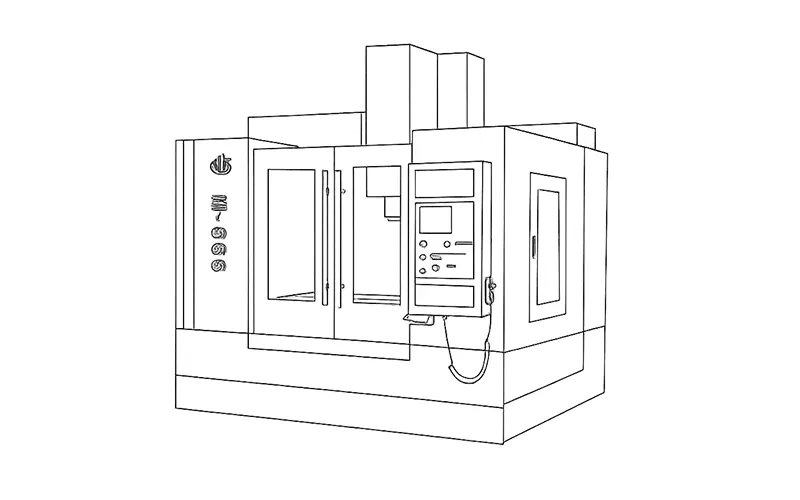

● All castings are cast by resin sand process, with beautiful appearance. All castings are subjected to secondary aging, with small thermal deformation and stable precision.

● The overall bed base has better waterproof performance; after chip removal, it is more suitable to form an automatic production line.

● X/Z direction adopts rectangular cast iron hardened guide rail, with large guide rail span (Z direction 430mm/X direction 280mm) guide rail system has stronger rigidity, better guidance, higher precision and better sliding performance.

● Main drive system, driven by frequency conversion or servo motor, Manual three-speed speed change, retains the characteristics of high torque turning, especially suitable for heavy cutting.

● The X/Z feed system adopts the screw center structure, advanced center of gravity drive technology (DMG), screw pre-stretching technology, and direct connection technology to achieve faster transmission speed and higher positioning accuracy.

● Two types of carriages and slides, one with single tool rest and one with double tool rest. You can also choose single tool holder + row tool, plus U drill and other configurations.

● X/Z-direction guide rail and lead screw adopt full protection structure, which has good chip removal and waterproof performance, reduces the wear of guide rail and lead screw, and improves the service life of guide rail and lead screw.

| Model | CK-5355 | CK5375 | |

| Maximum turning diameter of bed | 530mm | 530mm | |

| Maximum machining diameter | 530mm | 530mm | |

| Maximum turning diameter on the skateboard | 310mm | 310mm | |

| Maximum processing length | 500mm | 700mm | |

| Spindle end type and code | A2-8 | A2-8 | |

| Spindle hole diameter | 82mm | 82mm | |

| Headstock | Spindle speed range | Manual 3rd gear40~1500r/min | Manual 3rd gear40~1500r/min |

| Spindle maximum output torque | 282N.m | 282N.m | |

| Main motor output power | 7.5kw | 7.5kw | |

| Chuck | Chuck diameter/type | 250mm | 250mm |

| X-axis rapid traverse speed | 16m/min | 16m/min | |

| Z-axis rapid traverse speed | 16m/min | 16m/min | |

| X-axis travel | 350mm | 350mm | |

| Z-axis travel | 550mm | 750mm | |

| Standard tool holder form | Electric Quartet Optional: Double tool holder (270 pitch) Optional: vertical six-station Optional: electric square + straight row | Electric Quartet Optional: Double tool holder (270 pitch) Optional: vertical six-station Optional: electric square + straight row | |

| Tool size | Cylindrical knife | 25x25mm | 25x25mm |

| Machine weight | 2900g | 3200g | |

| Machine tool dimensions (L×W×H) | 2315x1720x1600mm | 2600x1800x1600mm | |

浙公网安备33071802889448号

浙公网安备33071802889448号